Introduction

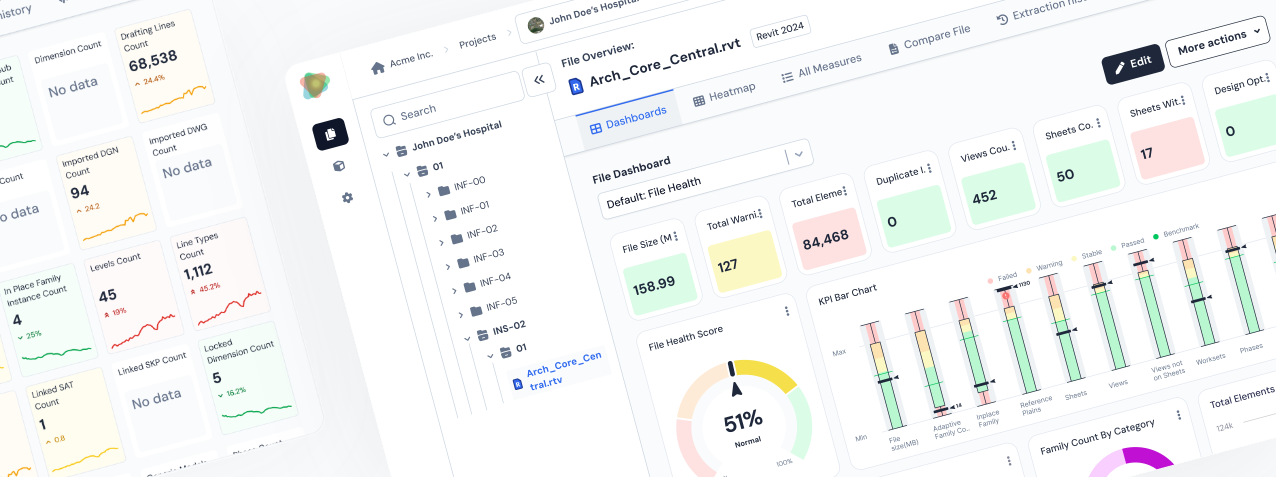

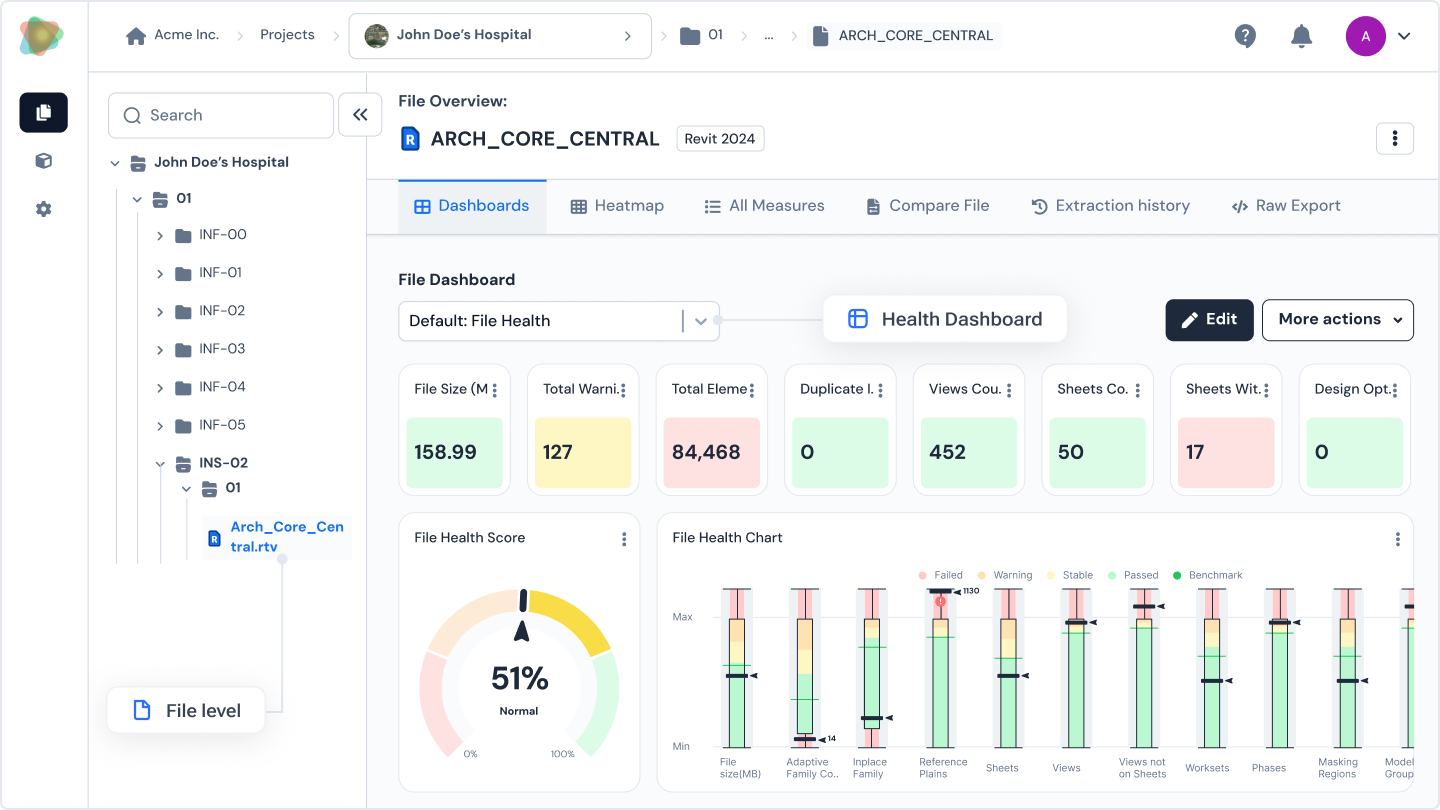

Case A - Model Health Check

- Warnings and collision issues;

- Unused families and geometry;

- View bloat (excess or unused views);

- File size bloat and unusually large linked models;

- Non-conforming naming conventions and parameter mismatches (worksets, types).

- Develop a lightweight Revit add-in that gathers model metrics (warnings, unused families, links, etc.).

- Aggregate and serialize the results into a structured JSON or XML report.

- Send the report to a cloud API for centralized storage and analysis.

- Visualize results on a management dashboard with filters for project, discipline, and time range.

- Optionally add automated recommendations, such as “delete N unused families” or “investigate linked model Y”.

- Schedule regular health checks (e.g. nightly or per commit) to maintain BIM quality baseline.

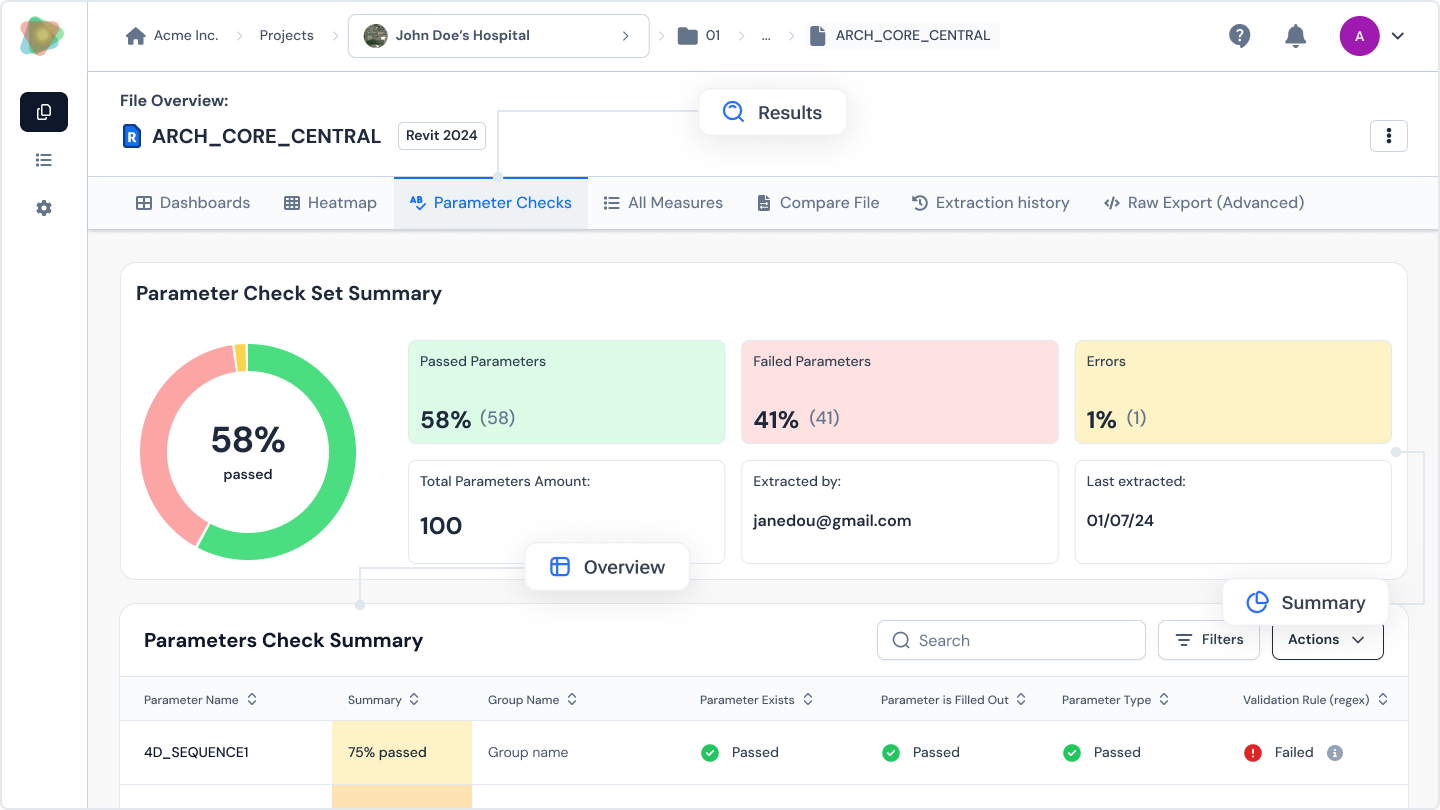

Case B - Parameter Control

- Missing mandatory parameters;

- Wrong parameter types (e.g. text instead of number);

- Non-conforming units or naming;

- Out-of-range values;

- Mismatched discipline-specific data (architecture, MEP, structural).

- Implement pre-submission validation in a Revit add-in that triggers automatically before model export or sync.

- Load validation rules (required fields, allowed values, data formats) from a central configuration.

- Scan the model for parameter mismatches or missing values.

- Display in-place warnings and offer one-click auto-correction using approved values.

- Optionally sync validation reports to a cloud dashboard for QA tracking.

- Allow a central administrator to update the shared parameter dictionary and distribute rule changes across all teams.

Case C - Smart Import & Export

- Filter only relevant categories and views;

- Rename exports based on project metadata;

- Compress and version packages automatically;

- Validate IFC or DWG exports for required attributes;

- Import approved models back into the project folder with correct metadata.

- Extend Revit with a custom export module that integrates via

DocumentExportAPI. - Apply project-specific rules for naming, file formats, and output structure.

- Generate and store export logs locally for QA verification.

- Invoke a cloud function to store export metadata and trigger status notifications (e.g. “Structural export ready for review”).

- Optionally extend the same logic to Autodesk Platform Services - for example, automate processing of uploads in Autodesk Docs or Model Coordination.

- Set up scheduled or triggered exports (CI-like pipelines) to maintain consistent deliverables without manual steps.

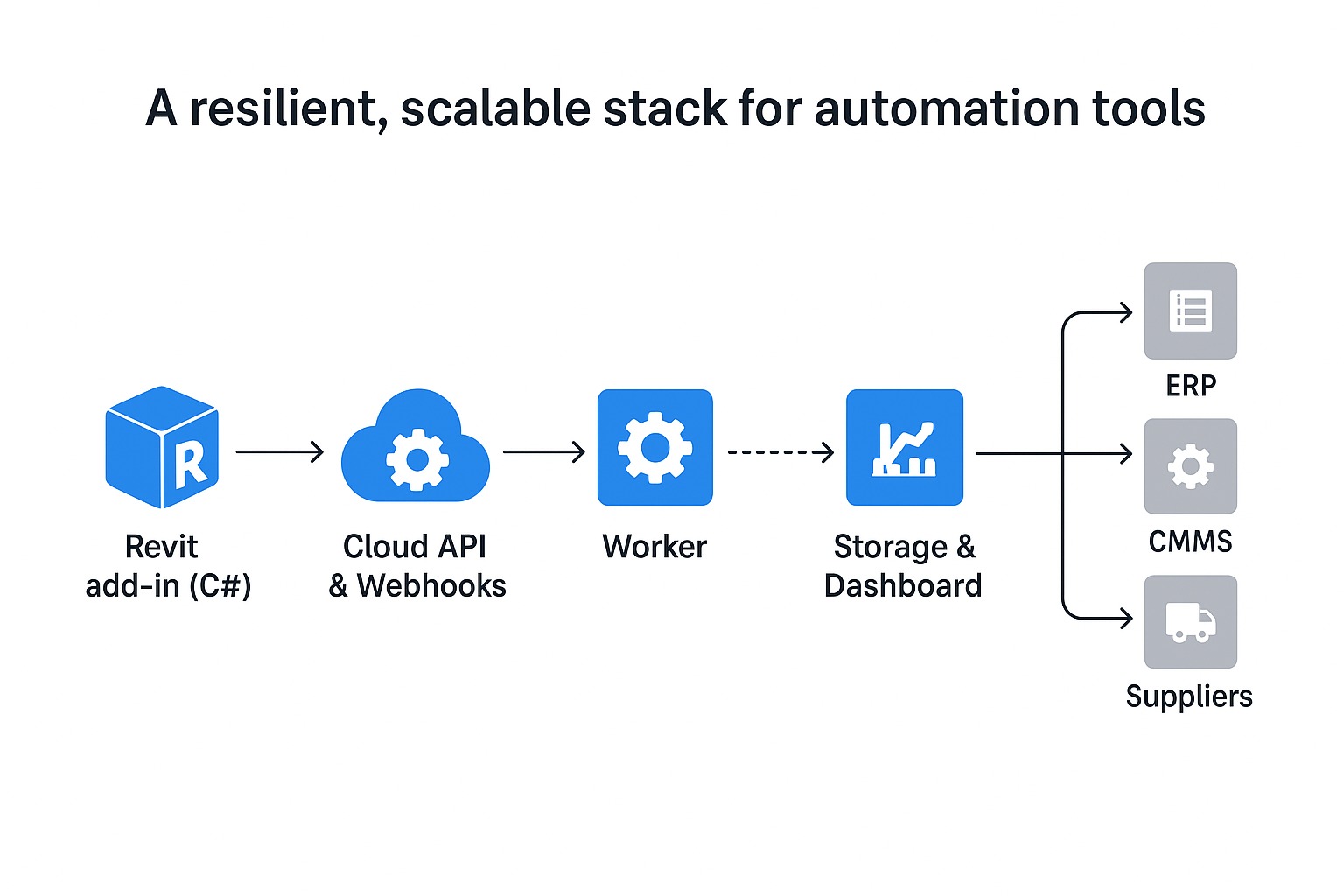

Recommended technical architecture

- Revit add-in (C#) - local data aggregation, interactive UI, async change push;

- Cloud API & Webhooks - receive events and enqueue tasks (RabbitMQ, Kafka, or managed queues);

- Worker - asynchronous processing for health checks, validation, exports;

- Storage & Dashboard - store reports, historical metrics, and show dashboards for managers;

- Integrations - ERP, CMMS, suppliers, Autodesk cloud or corporate storage.

- Keep the add-in lightweight - collect & validate locally, offload heavy processing to cloud workers.

- Maintain an authoritative corporate catalog (manufacturers, part numbers) for auto-fill.

- Add audit trails for all automated edits (who/what/when) to satisfy compliance and traceability requirements.

- Implement incremental exports and content hashing to avoid unnecessary full-package regenerations.

Example ROI (conservative scenario)

10 engineers:-

Routine time per engineer:

5 hours/weekfor checks, exports or fixes.

Calculation:10 × 5 = 50 hours/weektotal. -

Conservative automation saving:

60% of routine time- reasonable for scripted checks, bulk fixes and scheduled exports.

Saved time/week:50 × 0.60 = 30 hours/week. -

Annual saved hours:

30 × 52 = 1,560 hours/year.

Practical tips for rollout

- Start with a pilot on one project to tune rules and naming conventions.

- Focus first on the highest-value, repeatable tasks (warnings clean-up, required COBie fields, regular export packages).

- Provide rollback and preview modes for bulk changes (preview → apply → audit).

- Train teams on how automated recommendations fit existing workflows - automation should augment users, not surprise.

- Instrument early: capture metrics (time saved, number of issues fixed, RFIs reduced) so ROI can be measured and the scope expanded confidently.

Final Thoughts

References

- McKinsey - Decoding digital transformation in construction

- McKinsey - The impact and opportunities of automation in construction

- McKinsey - Delivering on construction productivity is no longer optional

- Autodesk - Customer stories / case studies

- Autodesk - Voyansi–RedBuilt case (digital transformation)

- ResearchGate - Effect of Building Information Modeling (BIM) on reduced construction time-costs: a case study

- ResearchGate - The impact of BIM on project time and cost: insights from case studies

- Construction Dive - Why construction productivity growth is lagging (commentary on industry productivity challenges)

Stanislau

Full-Stack Software Engineer